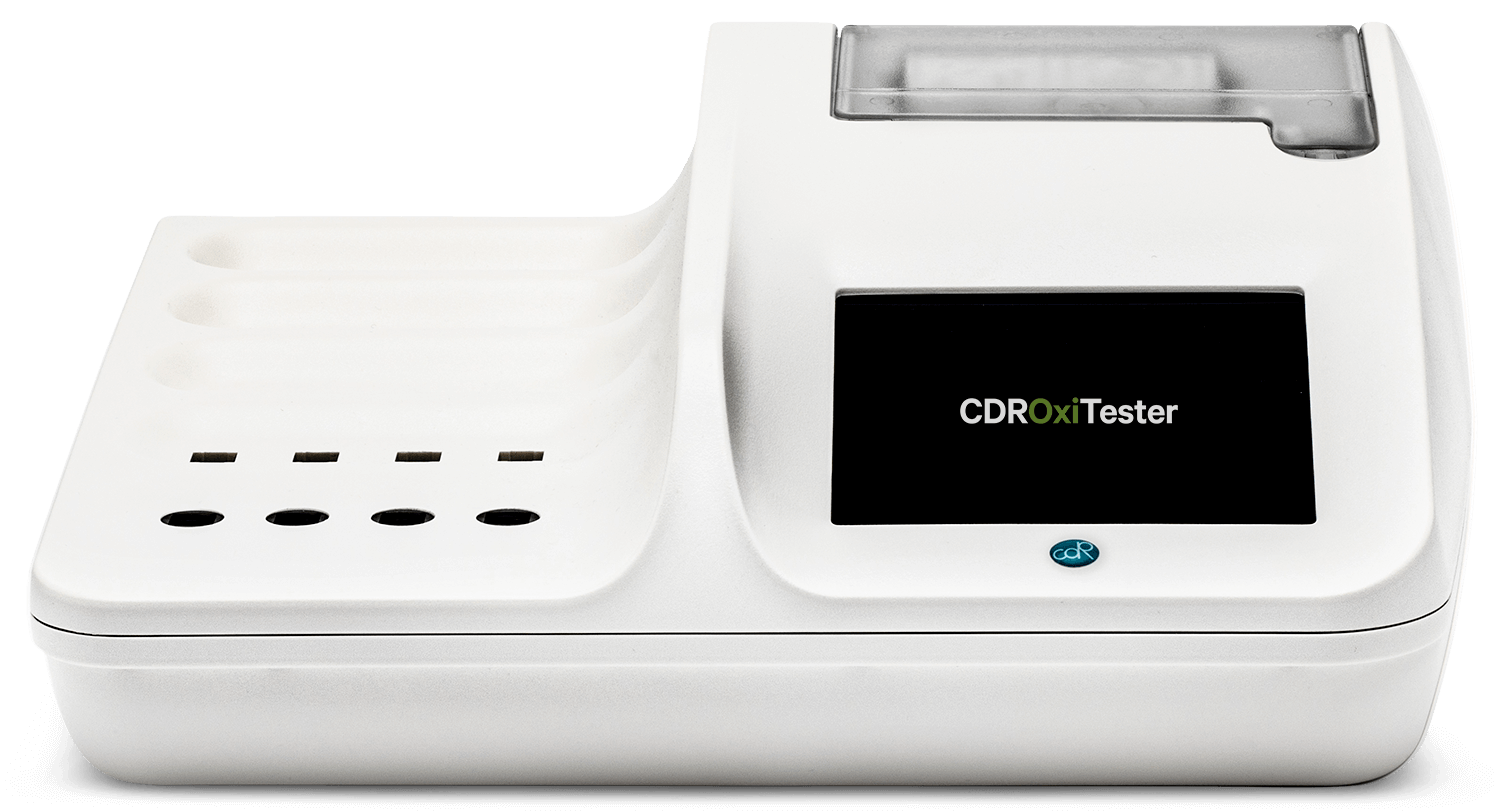

CDR OxiTester: Analyses of olive oil within your reach

CDR OxiTester is the analysis system of olive oil designed to be used at the olive oil mill without the need for specialised personnel or a chemical laboratory with extractor hoods and other equipment. All you need is a table top and an electrical outlet.

No need for well-equipped laboratories and chemical expertise

With CDR OxiTester you can analyse acidity, peroxides, polyphenols and stability index. Even operators without experience in chemical analysis and without an equipped laboratory can carry out analyses of olive oil in a practical and fast way.

The reagents, developed in the CDR research laboratories, are pre-filled into vials and ready to use. Analysis results are obtained in a few minutes with simple steps.

Also available in a portable version

With the CDR OxiTester Portable model you can carry out oil quality controls wherever you want.

Thanks to the lithium battery, you will be able to carry out analyses for an entire day without having to connect the instrument to an electrical outlet.

CDR OxiTester is:

Reliable

The instrument ensures results in accordance with reference methods. The use of LED reading cells guarantees high sensitivity, a wide measuring range and excellent repeatability of the results.

Simple

The analytical methods are simpler than traditional ones. The system can be used not only in the laboratory, but also on the production line in real time, by non-expert operators. In addition, the instrument has a Help function for step-by-step user guide.

Fast

The methods developed in CDR laboratories speed up the analysis procedures: sample preparation is absent or very simple and analyses are carried out in just a few steps. It is possible to analyse several samples simultaneously or manage the determination of several analytical parameters at the same time of the same sample.

Which model is the most suitable for your needs?

CDR OxiTester

- Complete analysis panel, supplied already configured

- Up to 16 determinations simultaneously

- Possibility of carrying out analyses of the same sample

- Integrated printer

- Full connections (LAN - USB - Bluetooth barcode/QR code reader)

CDR OxiTester Junior

- Partial analysis panel, supplied configured with 3 analyses of your choice, implementable

- Up to 3 determinations simultaneously

- Wireless connection to external printer

- USB connections

CDR OxiTester Portable

CDR OxiTester Portable consists of a Junior model equipped with:

- an internal lithium battery,

- a Bluetooth printer for printing analysis results

- a robust shockproof suitcase for safe transport.

Reduce waiting times to have a quality olive oil

By choosing CDR OxiTester you can check the quality of your oil without the need for external laboratories and improve your production process.