CDR BeerLab®: Quality control of your beer, in a quick and easy way

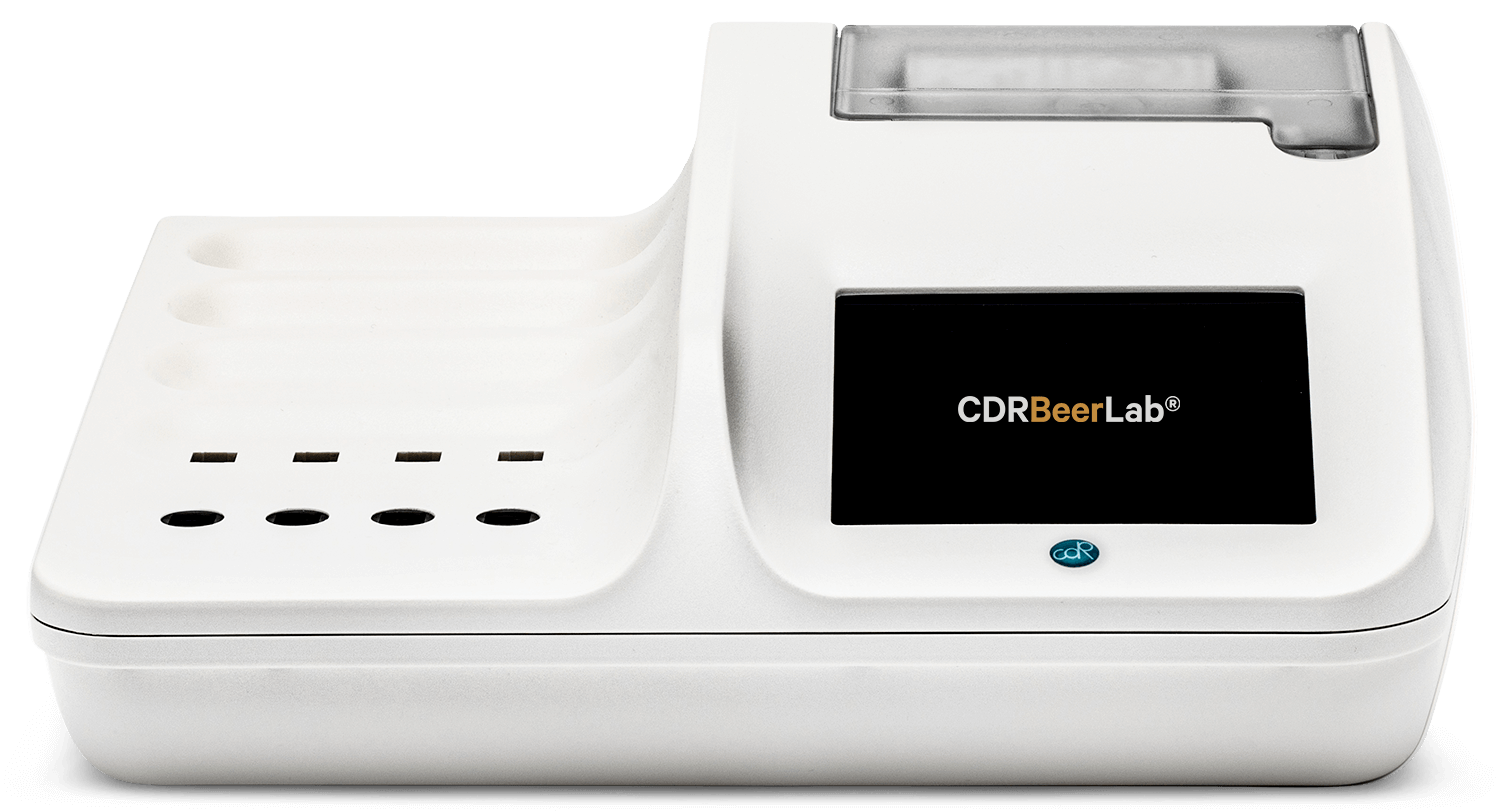

CDR BeerLab® is a simple, fast and reliable analysis system of beer.

A complete and compact instrument for monitoring every stage of the brewing process.

For every master brewer and breweries of all sizes.

Performing professional analyses more quickly

With the CDR BeerLab® analysis system, it is possible to carry out a wide range of analyses of beer, wort and water with just one instrument more quickly and easily than is possible with traditional methods - and all this independently, without the need for external laboratories.

Reagents are pre-filled into vials and ready to use, you do not have to handle toxic or carcinogenic agents, sample preparation is absent in the case of water or very simple in the case of beer and wort according to a method developed by researchers of the CDR laboratories. Results are obtained within minutes and are in accordance with those obtained with reference methods.

From hop management to bottling, the whole process is optimised

Personally manage every stage of brewing process with the analyses you need, in the shortest possible time. With CDR BeerLab® you can carry out a wide range of analyses. What you want, when you want it.

CDR BeerLab® is:

Reliable

The instrument ensures results in accordance with reference methods. The use of LED reading cells guarantees high sensitivity, a wide measuring range and excellent repeatability of the results.

Simple

The analytical methods are simpler than traditional ones. The system can be used not only in the laboratory, but also on the production line in real time, by non-expert operators. In addition, the instrument has a Help function for step-by-step user guide.

Fast

The methods developed in CDR laboratories speed up the analysis procedures: sample preparation is absent or very simple and analyses are carried out in just a few steps. It is possible to analyse several samples simultaneously or manage the determination of several analytical parameters at the same time of the same sample.

Which model is the most suitable for your needs?

CDR BeerLab®

- Complete analysis panel, supplied already configured

- Up to 16 determinations simultaneously

- Possibility of carrying out analyses of the same sample

- Integrated printer

- Full connections (LAN - USB - Bluetooth barcode/QR code reader)

CDR BeerLab® Junior

- Partial analysis panel, customisable configuration

- Up to 3 determinations simultaneously

- Wireless connection to external printer

- USB connections

Value your time

Discover all the advantages of our analysis system:

The experience of customers who have chosen CDR BeerLab®

Our customers' satisfaction is the real proof of the value of our analysis systems.

Stewart Poulter, Quality Assurance Brewer at Oakham Ales“For our size of brewery, the CDR BeerLab® is an ideal tool for QA and process control. It is very easy to use, without needing a lab background and the reagents are non-toxic so it’s easy to implement”.Read the Oakham Ales Case Study

Stewart Poulter, Quality Assurance Brewer at Oakham Ales“For our size of brewery, the CDR BeerLab® is an ideal tool for QA and process control. It is very easy to use, without needing a lab background and the reagents are non-toxic so it’s easy to implement”.Read the Oakham Ales Case Study Jen Reddish, Director of Quality at Prost Brewing Co.I would absolutely recommend the CDR BeerLab® to other brewers. The kits are straightforward, ordering is simple, and the system has really improved our workflow.Watch the full testimonial from Jen Reddish, Director of Quality at Prost Brewing Co.

Jen Reddish, Director of Quality at Prost Brewing Co.I would absolutely recommend the CDR BeerLab® to other brewers. The kits are straightforward, ordering is simple, and the system has really improved our workflow.Watch the full testimonial from Jen Reddish, Director of Quality at Prost Brewing Co. Alex Martin, Senior Chemist of Whiskey House of KentuckyCDR BeerLab® enables distilleries to bridge the gap between high-level analytical capabilities and everyday operational needs. Whether used in conjunction with HPLC or as a stand-alone solution, it empowers production teams to maintain product quality and consistency with speed and precision.Watch the full testimonial from Whiskey House of Kentucky’s Senior Chemist, Alex Martin

Alex Martin, Senior Chemist of Whiskey House of KentuckyCDR BeerLab® enables distilleries to bridge the gap between high-level analytical capabilities and everyday operational needs. Whether used in conjunction with HPLC or as a stand-alone solution, it empowers production teams to maintain product quality and consistency with speed and precision.Watch the full testimonial from Whiskey House of Kentucky’s Senior Chemist, Alex Martin- Paul Holden-Ridgeway, Head Brewer of BAD Co.’s“Since its installation, we have found the analyser to be accurate and easy to use. We are looking to list BAD Co. beer with a well-known national retailer and we wouldn’t be able to do that without in-house quality control using the BeerLab”.

- Robyn Bell, Tank Manager Cloudwater“The BeerLab allows us to measure our VDK levels accurately and quickly, reducing our tank occupancy and ensuring we are completely confident in the beers we are releasing”.

Reliable results are guaranteed

Frequently Asked Questions about CDR BeerLab®

A: The system’s reliability is confirmed by studies from universities and specialized institutes. Our clients worldwide attest to its effectiveness: Some methods are used by prestigious multinational groups

A: Each CDR test method is correlated with the corresponding international reference method, and in some cases is also adopted by accredited laboratories.

A: At startup, the instrument automatically checks the reading cell and blocks the analysis if an error is detected. In addition, CDR provides Control Solutions, samples with predefined results that allow users to regularly verify both instrument performance and operator accuracy. Integration with SAP further supports monitoring of the system’s status.

A: Because CDR BeerLab® analyzers are factory pre-calibrated together with their reagents, with calibration data embedded in the instrument and each reagent lot aligned to previous lots; an automatic self-check at every startup verifies performance, so routine user calibration is unnecessary, with fine-tuning available if necessary when aligning to alternative methods or legacy datasets. For a deeper explanation of how calibration is designed and managed, you click and read the full article

A: No, CDR BeerLab® requires neither maintenance nor periodic cleaning.

This is possible thanks to its optical technology based on an LED reading cell, which does not need calibration or periodic replacement, unlike traditional tungsten lamps or other more delicate systems. No drift over time, no corrective action required.

Its compact and robust design also makes the instrument ideal for direct use on production lines, even in demanding operational environments such as olive mills, wineries, breweries, or plants with industrial fryers.

Many of our customers have been using CDR BeerLab® for years, performing hundreds of analyses per week, without ever having to stop operations for maintenance activities.A: No Qualified technicians is needed: the system is intuitive and accessible to anyone.

A: Yes. CDR FoodLab® uses reagents in minimal quantities, significantly reducing operator risks compared to traditional methods. Additionally, it ensures sustainability through micro-analysis, which minimizes reagent use, waste, and emissions while maintaining safety and efficiency in food and beverage quality control. [More info ...]

A: Overall costs are highly competitive thanks to shorter analysis times, absence of maintenance, and long system lifespan based on LED technology.

Good beer is born under your control

Monitoring and managing your brewing process at every stage has never been faster or more intuitive. You can analyse your samples of beer, wort or water in total autonomy.