CDR BeerLab®: Quality control of your beer, in a quick and easy way

CDR BeerLab® is a simple, fast and reliable analysis system of beer.

A complete and compact instrument for monitoring every stage of the brewing process.

For every master brewer and breweries of all sizes.

Performing professional analyses more quickly

With the CDR BeerLab® analysis system, it is possible to carry out a wide range of analyses of beer, wort and water with just one instrument more quickly and easily than is possible with traditional methods - and all this independently, without the need for external laboratories.

Reagents are pre-filled into vials and ready to use, you do not have to handle toxic or carcinogenic agents, sample preparation is absent in the case of water or very simple in the case of beer and wort according to a method developed by researchers of the CDR laboratories. Results are obtained within minutes and are in accordance with those obtained with reference methods.

From hop management to bottling, the whole process is optimised

Personally manage every stage of brewing process with the analyses you need, in the shortest possible time. With CDR BeerLab® you can carry out a wide range of analyses. What you want, when you want it.

CDR BeerLab® is:

Reliable

The instrument ensures results in accordance with reference methods. The use of LED reading cells guarantees high sensitivity, a wide measuring range and excellent repeatability of the results.

Simple

The analytical methods are simpler than traditional ones. The system can be used not only in the laboratory, but also on the production line in real time, by non-expert operators. In addition, the instrument has a Help function for step-by-step user guide.

Fast

The methods developed in CDR laboratories speed up the analysis procedures: sample preparation is absent or very simple and analyses are carried out in just a few steps. It is possible to analyse several samples simultaneously or manage the determination of several analytical parameters at the same time of the same sample.

Which model is the most suitable for your needs?

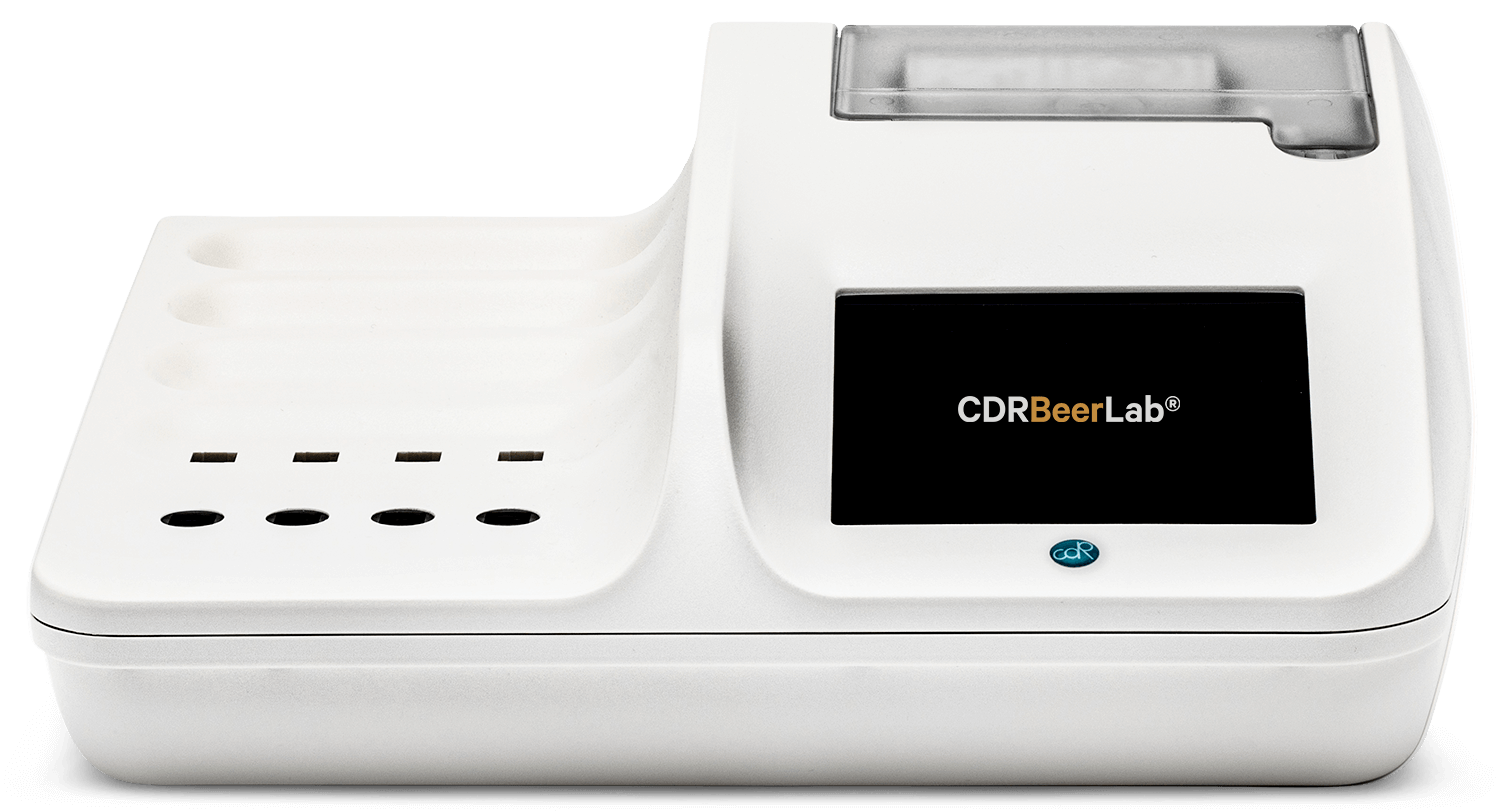

CDR BeerLab®

- Complete analysis panel, supplied already configured

- Up to 16 determinations simultaneously

- Possibility of carrying out analyses of the same sample

- Integrated printer

- Full connections (LAN - USB - Bluetooth barcode/QR code reader)

CDR BeerLab® Junior

- Partial analysis panel, supplied configured with 3 analyses of your choice, implementable

- Up to 3 determinations simultaneously

- Wireless connection to external printer

- USB connections

Reliable results are guaranteed

Good beer is born under your control

Monitoring and managing your brewing process at every stage has never been faster or more intuitive. You can analyse your samples of beer, wort or water in total autonomy.

The experience of customers who have chosen CDR BeerLab®

Our customers' satisfaction is the real proof of the value of our analysis systems.

Alex Martin, Senior Chemist of Whiskey House of KentuckyCDR BeerLab® enables distilleries to bridge the gap between high-level analytical capabilities and everyday operational needs. Whether used in conjunction with HPLC or as a stand-alone solution, it empowers production teams to maintain product quality and consistency with speed and precision.

Alex Martin, Senior Chemist of Whiskey House of KentuckyCDR BeerLab® enables distilleries to bridge the gap between high-level analytical capabilities and everyday operational needs. Whether used in conjunction with HPLC or as a stand-alone solution, it empowers production teams to maintain product quality and consistency with speed and precision.- Paul Holden-Ridgeway, Head Brewer of BAD Co.’s“Since its installation, we have found the analyser to be accurate and easy to use. We are looking to list BAD Co. beer with a well-known national retailer and we wouldn’t be able to do that without in-house quality control using the BeerLab”.

- Robyn Bell, Tank Manager Cloudwater“The BeerLab allows us to measure our VDK levels accurately and quickly, reducing our tank occupancy and ensuring we are completely confident in the beers we are releasing”.